Vertical Integration.

Capabilities

- 30 computer numerical control (CNC) machines

- 30 highly skilled machinists

- 10′ x 26′ and 13′ x 20′ double column gantry mills

- Two Mazak Variaxis 500 and 630 two pallet 5-axis vertical machining centers

- Zeiss Contura G2 RDS 100 / 1600 / 600 CMM machine

- 14 CNC vertical mills

- Two CNC horizontal pallet changing machines, 60″ capacity

- Four CNC horizontal boring mill

- Five-axis programming capability

- Two large five-sided machining gantry mills

- 0.001″ tolerances on milling operations

- 0.0005″ tolerances on turning operations

- Machined armor grades AR 500, 46100, and 12560

Anderson Mass 5

- 5-Axis Machining Center

- 12’ x 26’ x 3.9’ Working Envelope

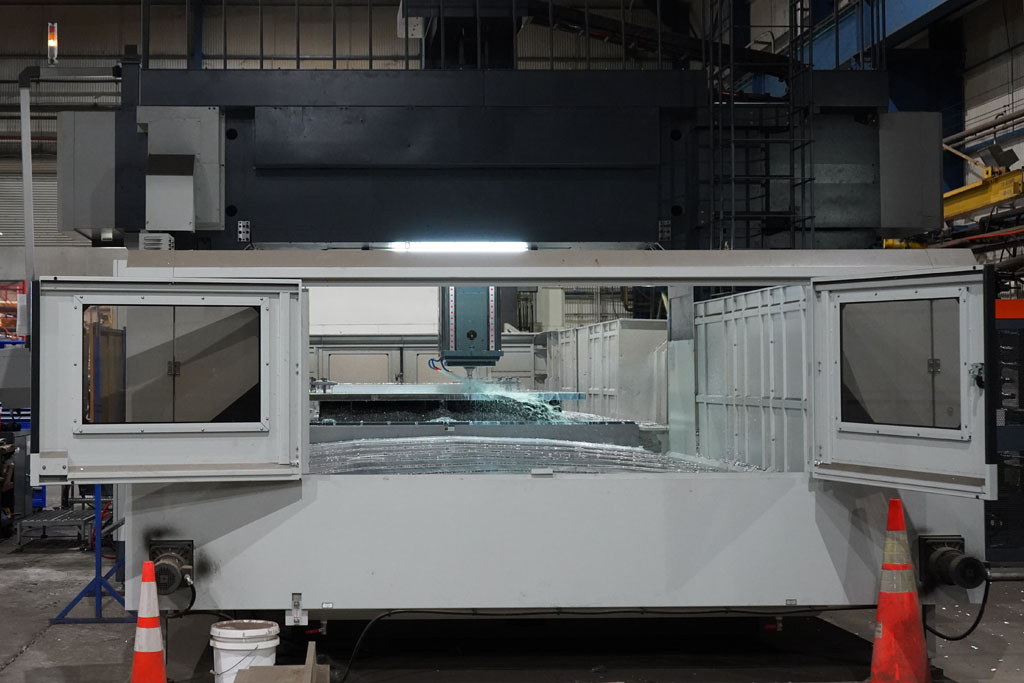

V-Tec

- Vertical Bridge Mill

- 20’ x 15’ x 17’ Working Envelope

Okuma

- Double-column Machining Center

- 10′ x 26′ Travel

- Five-sided machining with horizontal head

- Great for heavy steel milling

- 10,000 RPM

Onsrud 3-Axis

- 10′ by 20′ Travel

- Perfect for aluminum plate work

- 24,000 RPM spindle

- Vacuum table for quick set-up and change-out

Onsrud 5-Axis

- 15′ x 35′ Travel

- Perfect for aluminum plate work

- 24,000 RPM spindle

- Vacuum table for quick set-up and change-out

Parpas Dinamika Horizontal Machining Center

- Made in Italy

- 28’ x 8’ x 10’ Working Envelope

- Large Weldments and Plates