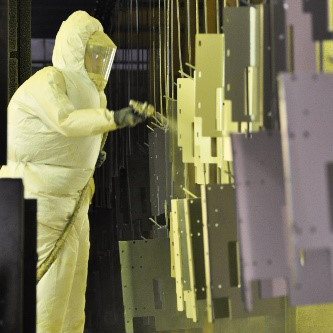

Powder Coating Technology.

JWF Industries has the largest non-dedicated powder coating line east of the Mississippi River in part size, weight, and quantity of parts per day.

Capabilities

- 60,000 square foot automated powder coating / wet coating CARC paint line

- Blast, prime, paint, and powder coat

- Pre-heat oven

- Wet coat and bake booths (all 20′ x 20′ x 60′)

- Polyurethane, water, and epoxy-based paints

- Military and commercial requirements

- 2,100′ conveyor capable of handling 6,000 pounds per part

- Large part paint line with 10′ x 20′ x 30′ part capability

- Six-stage pre-treatment for steel with steel shot blast

- Blast capabilities to SP5 / NACE #1 finish

- Direct to metal

- Heavy mill application

- Custom part making and part packaging

- Part sub-assembly, part assembly, and part kitting

Automated Paint Line

- 60,000 square foot powder coating / wet coating (CARC) paint line

- 2,100′ conveyor capable of handling 6,000 pounds per part

- Six-stage chemical pre-treatment

- Seven-stage stainless steel washer with phosphate coating system

- Zinc phosphate

- Polyurethane, water, and epoxy-based paints, military and commercial requirements

- Custom part making, custom part packaging, and part kitting

Powder Coat Paint System

20′ high x 20′ wide x 40′ long

- Wheelabrator model A3-45716, drive-through shot blast booth

- Wheelabrator drive-through paint spring booth

- Drive-through 500 Deg F gas fired driving oven, 20′ x 50′ x 10′

Large Part Drive-Through Paint Booth

20′ high x 20′ wide x 60′ long

- 20′ x 20′ x 60′ steel grit blast booth (on line)

- 18′ x 20′ blast booth

- 100′ x 20′ x 20′ rail car capable enclosed paint room

Ferrous Metals

- TT-C-490 Cleaning, Method I, Method II, Method III

- TT-C-490 Pre-Treatment Type III, Type IV, Type VI

- DOD-P-15328 Pre-Treatment

- A-A-59166 Moisture Cure Urethane Anti-Skid Technology

- MIL-DTL-53022 Epoxy Primer

- MIL-PRF-23377 Chromated Epoxy Polyamide Primer

- MIL-PRF-85285 High Solids Polyurethane

- MIL-DTL-24441 Epoxy Polyamide Primer and Topcoat

- MIL-PRF-32348 Powder Primer and Topcoat

- MIL-PRF-24714 Epoxy Powder

- MIL-DTL-53039 Top Coat

- MIL-PRF-22750 Top Coat (interior only)

- MIL-PRF-85285 High Solids Polyurethane

Non-Ferrous Metals

- TT-C-490 Cleaning, Method I, Method II, Method III

- TT-C-490 Pre-Treatment Type III, Type IV, Type VI

- DOD-P-15328 Pre-Treatment

- A-A-59166 Moisture Cure Urethane Anti-Skid Technology

- MIL-DTL-5541 Chemical Coating Aluminum

- MIL-DTL-53022 Epoxy Primer

- MIL-PRF-23377 Chromated Epoxy Polyamide Primer

- MIL-DTL-24441 Epoxy Polyamide Primer and Topcoat

- MIL-PRF-32348 Powder Primer and Topcoat

- MIL-PRF-24714 Epoxy Powder

- MIL-DTL-53039 Top Coat

- MIL-PRF-22750 Top Coat (interior only)

- MIL-PRF-85285 High Solids Polyurethane